Keeping your load safe and secure – at all times!

According the police, approximately 25% of accidents involving trucks are actually caused by inadequate load securing. This results in annual economic damages reaching into the millions. Correct load securing is required by law and is the responsibility of the shipper, the driver, and the vehicle owner.

To ensure that your products or belongings safely get from A to B, and so that you do not have to worry about transport, when rented our vehicles are already fitted with load securing systems. Depending on the vehicle model, our vehicles will be equipped with one of the three integrated load securing rail options. We would like to provide an overview so that you can familiarise yourself with the different load securing rails and with the most common types of load securing.

Load Securing: Rail systems

The three rail types that are used at Sixt:

- Airline rail

- Rod lashing bar

- Combination anchor rail

Matching end fittings for the rail system built into Sixt commercial vehicles can be obtained from various suppliers, for example here. We would like to provide you with an overview in this respect:

- Airline rail + end fitting, single-stud OR double-stud

- Rod lashing bar + flat hook end fitting

- Combination anchor rail + end fitting

Airline rail

With the airline rail you can assume a high lashing point. They are no longer only available as steel, but are also available as lightweight materials. These types of rails can also be combined in various ways. End fittings, barrier beams, or lashing straps can easily be used with them. Airline rails can be mounted almost anywhere in the vehicle thanks to different profiles.

Rod lashing bar

Rod lashing bars are also generally made from aluminium. They are perfectly suited to being horizontally mounted on the vehicle wall. The rod lashing rail is very suitable as an additional safeguard, since it can be used both with lashing straps and locking bars. Incidentally, rod lashing bars are also known under the names of stud lashing rails, stud rod lashing bars, or rod lashing rails.

Combination anchor rail

The combination anchor rail is often made of galvanised steel or aluminium. Whereby the stability of the aluminium lashing rail is equivalent to that of the steel lashing rail. The weight saving is enormous, for example 1m-long aluminium combination rails are 1.5 kg lighter than the steel version. You can assume two different hole sizes with the locking rods. Thanks to the ring at the end, you can connect the strap end hooks when using two-piece lashing straps. You can also easily pull the strap through when using one-piece lashing straps.

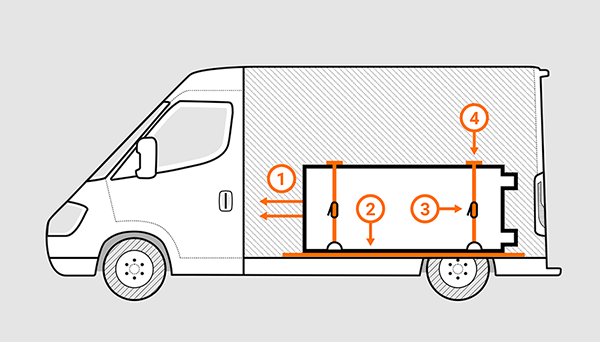

The proper use of lashing

Since 80% of all loads are applied with a load restraint via rail systems, this means that you are using lashing (lashing straps) to secure your load. These press the load onto the loading surface, thus increasing the friction between the load and the loading surface.

With ratchet lashing straps you should always lash everything down in order to attain an ideal interlocking connection.

Expert tips for the proper care of lashing

Incidentally, you should always maintain your straps dry and free of grease. Also soil and dirt should always be removed from them so that the straps properly grip, and so that the fittings do not break. Refrain from knotting the lashings, and before using the straps always carefully check that they have excellent load values.

Another helpful tip for securing the load: Please also secure loading equipment. Keep the loading area clean, so that the load will not be damaged and will adhere better to the vehicle floor.

Types of load securing

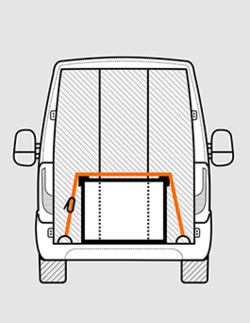

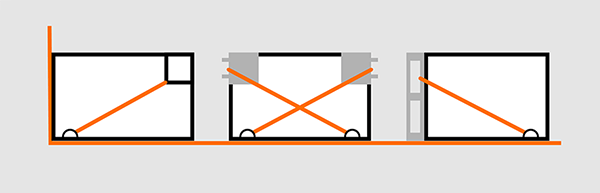

Friction locking

The lashing also presses the load onto the loading surface. The friction between the load and the loading surface is increased, thus firmly holding the load on the loading surface

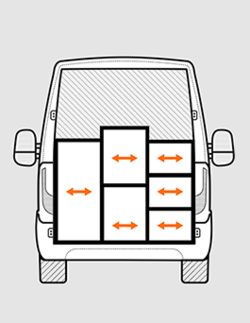

Interlocking connection

All-round, seamless application of the load against the load space boundaries. The load mutually holds itself in place.

Combined

The term “combined load securing” means using interlocking connection together with friction locking load securing.

The side and rear securing is achieved for example by lashing down, and by directly loading the cargo into locking elements.

Load Securing – Interlocking with equipment

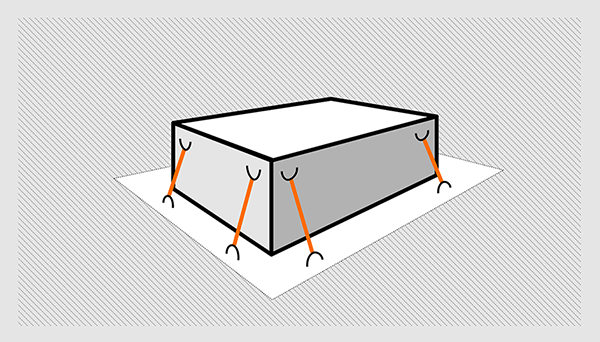

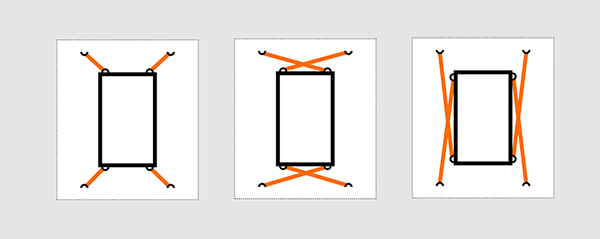

Transverse lashing/Diagonal lashing

This method is mainly used for heavy load applications. The load is directly connected to the loading surface with chains or lashing straps. Whether it is transversely or diagonally lashed depends on the position of the lashing eyes on the load, and on the load carrier. In each case the most favourable angle must be selected. With transverse lashing at least 8, and with diagonal lashing at least 4 lashings are required for professional securing.

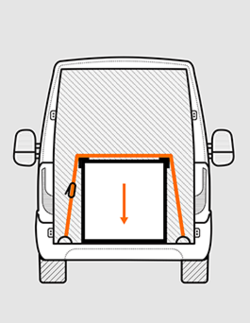

Top or side lashing

If the load cannot be placed against the end wall due to the load distribution plan, the load is secured with top lashing.

Physics 101: What forces are at work?

- Mass force: Also called “inertial force” or “centrifugal force”. This refers to the tendency of the load to oppose a change in its state of motion. The mass force counteracts any acceleration or deceleration.

- Gravitational pull: The gravitational pull is the force with which the load presses down on the loading surface due to the force of gravity.

- Frictional force: Occurs between surfaces, counteracts shifting of the load and thus helps in load securing. Securing force: is the force that is applied in addition to the friction force to secure the load against movement. It is calculated from the mass force minus the frictional force.

More tips on how to secure a load safely – what to look out for when using lashing straps:

- Check for correct GS Logo and MOT mark

- Check LC value with details of tension force

- Check tensioning strap fits the load tensioning rail

- Check strap is in perfect condition with no cuts, damage or wear and tear

Why should I secure my load?

- You will protect yourself and others from accidents and injuries.

- You will get your load safely and without damage to your destination.

- Your van or truck remains free from damage, saving you insurance and repair costs.

- You will avoid breaking the law and ending up paying high fines

Load Securing with a Van Hire

At Sixt, you can purchase at an additional cost during the vehicle rental transaction online or directly at our rental locations lashing straps and lashing gear appropriate for the load securing devices fitted inside our vehicles. Furthermore, you will find optional extras such as furniture dollies and sack trucks which will facilitate lifting, moving, and loading items. Additional aids and packing materials such as moving boxes complete our offer and will turn you into a transport professional simply and easily. Everything you book will be ready and waiting to be picked up at one of our branches in London, Bristol, Manchester or any other SIXT location in the country.